Danelaw Pitched Roofing

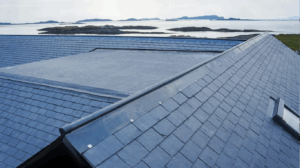

The Isle of Luing is one of the Slate Islands in the Inner Hebrides, in the west of Argyll in Scotland. Its charm lies in its natural beauty and unspoilt peaceful scenery looking out to the Inner Seas but is very exposed to the elements. Being coastal and located in BRE’s Wind Zone 4, properties need to be built with robustness and durability in mind.

The Danelaw SwiftRidg® Roll Top Ridge and Hip System, a new and innovative GRP product from Hambleside Danelaw, has been BRE tested to resist wind speeds exceeding 110mph. Comprising completely of corrosion resistant components and a unique concealed omega shaped fixing bracket to avoid any penetrations through the system, the SwiftRidg® was installed along all the ridge and hip lines.

An attractive and viable alternative to the traditional lead roll top ridge and hips, SwiftRidg® was installed on two properties along with Samaca Prime Slates on roofs covering an area of approximately 240m2; a perfect opportunity to showcase the neat and clean lines of the system.

Roofing contractors Kevin Mackie and Kieran Rowan admitted they were sceptical at first, as it is the first complete system of its kind, but with Paul Lambert (Hambleside Danelaw’s Field Technical Support) on hand, in addition to clear installation guidance they were impressed with the speed and ease of installation.

Kevin and Kieran had been contracted by Chris Parr Joinery and Building; and once the roof was complete, Chris Parr stated that “It looked great!”. The photos capture the beauty of the location, and the finish of the roof is clean, tidy and unobtrusive.

The SwiftRidg® is patent pending (Patent Application No. 2308115.1) and comes with a 20-year guarantee. Hambleside Danelaw also manufacture the SwiftRidg®+, which offers a ventilated option for ridge where required.

Express Lofts recently refurbished a residential property roof in Maidstone; re-tiling hip to gable, with a full width rear dormer.

When planning the installation, company director Dean Morris chose the unique Danelaw InVerg® interlocking dry verge system for plain double lap tiles. InVerg® has a patented design, which offers improved weather and wind resistance without reliance on mortar (GB Patent No: 2586153).

“I thought it was great…left a quality finish”, Dean said, “the ridge cap fits perfect”. Express Lofts purchased the InVerg® system from one of Hambleside Danelaw’s online stockists, Roofing Superstore. Ryan Holdford, Category Manager for Roofing stated “We’ve been stocking Hambleside Danelaw products for close to 15 years now which is a testament to the quality of their products and the high level of service they provide. They have been an ever-present figure on Roofing Superstore since we were founded providing high quality roofing solutions to both Tradesman and DIYers and contribute massively to the industry”.

So impressed was Dean, Express Lofts will now be offering the InVerg® as an option to all future customers, a great endorsement!

To learn more about InVerg®, fill in the contact form or email them on marketing@hambleside-danelaw.co.uk.

P.A. Leaford Traditional Roofing Tiler and Slater has recently completed two refurb/new build roofing projects in Cambridgeshire using Hambleside Danelaw’s CON6+ Dry Fix Ridge and Hip System purchased from Watts Roofing’s in Cambridge.

P.A. Leaford is a father and son roofing company built on the pride of workmanship with 25 years of experience. Based in Soham, Cambridgeshire, Wade Leaford joined 11 years ago; working alongside his dad, Paul Leaford. Their projects range from new builds to refurbishment, the duo have with decades of history attached to them.

Paul said:

“We bumped into Hambleside Danelaw on a site when the materials were provided by the main contractor. Since then, the CON6+ roll out ridge kit has been our number one choice, we recommend to our customers. We find the quality of the product and the materials used are far superior to other kits, giving us confidence on every install.’’

As previously mentioned, P.A. Leaford purchased Hambleside Danelaw’s CON6+ Dry Fix Ridge and Hip System from Watts Roofing Supplies in Cambridge. Watts Roofing Supplies was founded in 2010, located in Hertfordshire and Cambridgeshire. Watts Roofing believe in “building close customer relationships based on great customer service, supplying both Pitched and Flat Roofing products, insulation, cladding and commercial sheeting,

We have had an excellent relationship with Hambleside Danelaw for many years now, and have championed their products based on quality, and the fact they are always innovating and looking to expand their roofing solutions for our customers.”

Dan Spurling, Branch Manager at the Cambridge branch said:

”P. A. Leaford are a relatively new, but valued customer, of Watts Roofing in Cambridge; buying a range of primarily pitched roofing products.”

To get in touch with Watts Roofing Supplies please call 01223 491711, email cambridge@wattsroofing.co.uk or visit them in branch at Unit 1, Fielding Industrial Estate, Fulbourn, Cambridge CB21 5ET. To find out more about Watts Roofing Supplies’ other branches go to their contact page.

BS 5250 explains how underlays can help with roofing ventilation.

Hambleside Danelaw’s LR180 was selected for this project due to its high durability and heavier, premium weight. DMG Services Group Ltd got the underlay from One Stop Roofing Supplies, a stockist of Hambleside Danelaw products.

Darren McGhee, Managing Director of DMG Services Group Ltd, said “When pulling it across the open rafters, from right to left, its resistance to wind loads is second to none,” describing them as “a joy for roofers”.

East Kilbride, a town outside of Glasgow, falls within Wind Zone 3, meaning a range of our underlays would have been suitable for the housing development.

Hambleside Danelaw Underlays

Danelaw offers a variety of tile and slate underlays, with some having an option for a tape-to-tape system to remove the need for restraining batons at the lap line. Our range features 5 grades of membranes, which are available in two widths, ensuring customers have plenty of choice no matter which wind zone the development is in.

Extending our product range, we have also introduced Rewasi Top UV+ to provide roofers and specifiers with more options. Rewasi Top UV+ is an underlay made with Linopore® technology, which increases the product’s resistance to heat and UV, and therefore aging. Rewasi Top UV+ is classified as low resistance, or vapour permeable, which contributes to the ventilation of the completed roof.

To find out more about Danelaw underlays please get in touch with us through our contact page, or give us a ring on 01327 701 900. We will also be offering a course on our new learning platform, the Hambleside Danelaw Hub, about underlays, which will be available in the next few months. To learn more about the Hambleside Danelaw Hub, register your interest here.

A roofing contractor’s ethos that “only the best will do” has been recognised by a one of the leading quality national housebuilders.

Roof Plus, based in Chester, has been Redrow Homes’ preferred subcontractor in the North West for almost a decade, because of the quality of its work. That superiority has been recognised- again- with the winning of the 2019 Health & Safety Excellence Award at Redrow’s North West supply chain conference.

The Award is the latest Redrow accolade won by Roof Plus, complimenting Best Subcontractor NW and Subcontractor of the Year.

Where possible, Roof Plus installs Hambleside Danelaw products, using Danelaw Eaves Carrier and Low Profile Dry Valleys extensively across Redrow’s house designs, and Hambleside Danelaw’s innovative GRP roofing system Dryseal on flat roof dormers where appropriate.

“We have a positive culture towards quality in everything we do, from the products we choose to the way in which we install them and work on site. In our opinion, the Hambleside Danelaw range is the best on the market,” explains Roof Plus director Russel Witney. “That has clear synergy with Redrow’s provision of a quality home where only the best will do.

“All our work is completed ‘in house’ by directly employed roofers: thus they are committed to doing a quality job in all aspects, and have no reason to cut corners. All our roofers undergo thorough training, in product installation and site safety. It helps ensure optimum quality of build, done correctly, and thus minimising any future issues or remedials. We are not the cheapest, but the fact that we have such a long-standing partnership with Redrow proves we deliver best value.”

Adds Andy Fell, National Sales Manager-Dryseal at Hambleside Danelaw, “We know our products add value in their quality and ease of installation. It is great for our partner contractors to be recognised for the quality and value of their product and service.”

An award-winning roofing merchant reckons it is set to win even more, having added Danelaw GRP roof accessories to its portfolio.

Watts Roofing, founded just a decade ago, already has three branches across the East Midlands, and claims to be one of the fastest growing independent roofing merchants in the region. Its performance is endorsed by its winning of the Business Excellence Forum & Awards (BEFA) Best Manufacturer/Wholesaler trophy. Specialising in slates and tiles, it now stocks Danelaw’s full range of GRP valleys and roof ventilators.

“We aim to be the best, in product, service, customer support and speed of delivery,” explains director Shane Watts. “Local roofers are choosing us because we follow through on our promise, and are reliable. To continue to fulfil our ethos of offering the best, we switched to Danelaw, as we recognised the brand is the market leader in GRP valleys. We added the vents on top to give our customers a wider selection of products to choose from.”

The Danelaw brand of pitched roof ventilation accessories features a raft of pioneering- often patented- solutions designed to provide quality products that are fully compliant with all relevant Regulations, cost-competitive and roofer-friendly. The entire range of GRP roofing accessories is manufactured by Hambleside Danelaw at its state-of-the-art, purpose built factory in the heart of the UK.

A small development comprising of just 30 homes is now part of the picturesque village of Old Stratford in Milton Keynes.

Danelaw Open Valley for Slate Roofs

Morris Roofing and Leadworks is an established but expanding roofing contractor based in Bletchley, covering Buckinghamshire, Hertfordshire, Bedfordshire, Oxfordshire and Northamptonshire. As members of the NFRC (National Federation of Roofing Contractors) they offer quality service from inception to completion.

Morris Roofing and Leadworks were chosen for the installation of the slate and clay tile roofs on the Abbey Mill Homes project, incorporating three Danelaw dry fix products.

‘Dry fix’ are mechanically fixed products offering a mortarless application. The NHBC have recognised the advantages of mortarless dry fix products and encourage their use to reduce the risk of incurring future remedial works due to mortar failure. BS 5534 Code of practice for slating and tiling and NHBC require that all ridge and hip tiles now be mechanically fixed.

Danelaw Dry Fix Valley Trough for Tile Roofs

Danelaw CON6+ is a universal dry fix ridge and hip system, and was used on all the ridges. The patented gasket adds flexibility and allows compatibility with most commonly available ridge and hip tile profiles, including baby ridges.

The other products used were the original dry fix valley trough for the clay tile roofs and the open valley trough on the slate roofs. Both made from GRP, providing secure drainage for inclined roof valleys. The dry fix tile valley trough design eliminates the need for counter battens and special eaves closure pieces.

GRP products also offer advantages over traditional materials such as lead. They are simple and quick to install, have substantially lower costs than lead, no value to the thief, are thermally stable and have no harmful run-off or staining.

Danelaw CON6+ Ventilated Dry Ridge and Hip System

Lee Morris, Director of Morris Roofing and Leadworks and The Roofing Centre in Bletchley said ‘Danelaw products used on this project were easy to install and gave us peace of mind knowing that quality products were used in conjunction with the ten year guarantee we offer’.

To download the printable pdf version, please click here

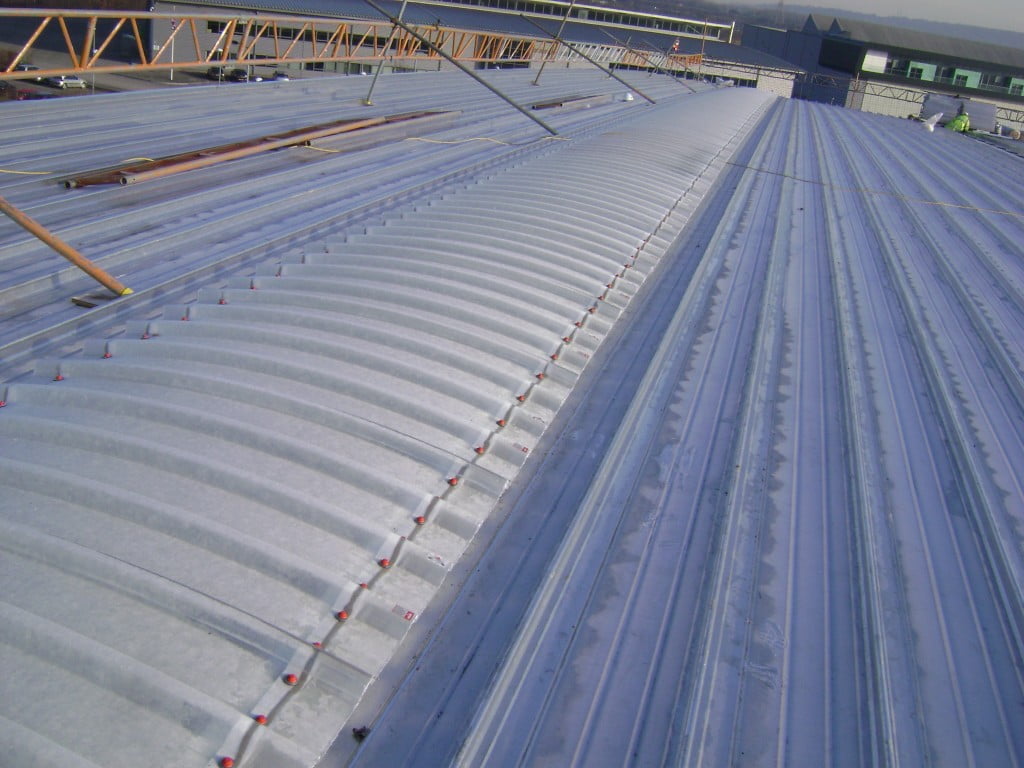

Paul Rosevear with 30 years of experience in the roofing industry has completed a unique project at Plymouth Ferry Port.

The project involved three steel oil tanks with an ongoing issue of corrosion due to their exposed location at the port. Paul was asked to find a solution for protecting the top edge detail of the middle oil tank.

Martin Daw and Joe Reeves from RSL Plymouth recommended Danelaw’s lead alternative flashing; Fast Flash. Fast Flash is a flexible and fully self-adhesive flashing, perfect for waterproof

sealing.

After a successful trial, it was decided Fast Flash was the perfect solution for the corroding edge detail.

Before applying the flashing, it was important to clean off and dispose of any flaking material to the edges, followed by applying a primer to the rusted areas to ensure Fast Flash would adhere properly. It was cut into lengths of 800mm for ease of application to the 50m circumference of the tank. A J-roller was used to make sure the flashing had good contact with the surface and to take out any air.

The project took 5 days to complete; Paul said ‘Fast Flash is very easy to apply and very sticky which helped. It had a neat and clean finish similar to lead and I would easily use this over other lead-replacement products on the market’

There are plans for the other two tanks to follow suit after the successful application of the Fast Flash to the first oil tank.

To download the printable pdf version, please click here

Breckland Roofing used a mixture of Hambleside Danelaw Pitched Roofing products including the market leading dry fix valley troughs

Towards the end of 2016, Norfolk based contractors Breckland Roofing completed a new development project in Attleborough. The project featured a mix of 60 properties from housing association to affordable homes and private dwellings accompanied by a range of Hambleside Danelaw’s Pitched Roofing Products.

Approximately 200 Hambleside Danelaw dry fix valley troughs were installed along with the universal dry fix ridge and hip system and interlocking dry verge for tiles. When asked why Breckland Roofing uses Hambleside Danelaw, David, Site Contracts Manager, was extremely positive with the product quality, ease of installation and durability “We are very happy with Hambleside’s products and service. We can give them to the roof tilers to take to site and know they will fit them without problems”

Our tried and tested range of flashing products help to maintain a watertight roof, ensuring your roof junctions are durable and sound for years to come. Contact us for more information on our product ranges or visit our roof flashings section.

Hambleside Danelaw’s dry fix valley troughs have been keeping UK roof junctions durable and sound for 20 years. They have once again been specified again as the ideal product for a project located in Tiverton, Devon. Contractors Kilbride Roofing have been using Hambleside Danelaw for many years “we find the products to be well made to a consistently high standard, robust for site handling, easy to use and good value for money.”

This particular development for a UK based residential developer is currently ongoing, with approximately 200 HDL DVLPT’s already installed. The site of 250 houses is principally for open market sale but contains proportions of affordable and social housing.

HDL DVLPT – Dry fix valley trough for low profile tiles

The HDL DVLPT dry fix valley trough for low profile tiles is the perfect lead alternative, offering time and money savings on site. As well as the similar aesthetics, GRP has none of the associated health and safety risks that arise when working with and handling lead. Having no scrap value and deterring theft minimises the risk of further damage and losses on site during and after installation.

Alan Godfrey from Kilbride Roofing commented “We continue to use a wide range of pitched roofing products from Hambleside Danelaw and find their products to be reliable and good value, the sales staff is knowledgeable and the products are delivered promptly and efficiently.”

Take a look at our dry fix valley troughs for further product specifications and details.

Alistair Tirns, Project Manager at Graham Roofing commented, he was “very pleased with the ease of use of the product the high quality and the finished appearance” and that Hambleside Danelaw is his preferred choice of roof vent.

Alistair Tirns, Project Manager at Graham Roofing commented, he was “very pleased with the ease of use of the product the high quality and the finished appearance” and that Hambleside Danelaw is his preferred choice of roof vent.

John Silverwright from the supplier, SIG Asphaltic, commented that he was “pleased with the product and service to this site for Dundee Council and Graham Roofing and will continue to use Hambleside Danelaw for further phases and projects in the future.”

Visit our tile vent page for more information on the Marley Modern type tile vent.

Works started on a new housing development last June on part of the old Beach Coach Station in the centre of Great Yarmouth. The newly built Royal Britannia Crescent consists of nineteen houses with gardens and parking and is the first initiative from the Norfolk Development Company (NDC). Hambleside Danelaw’s original Dry Fix mortarless GRP Valley Trough has once again been selected as the best product for the complicated crescent shaped roof.

The crescent shape of the houses is a very shallow curve; therefore the number of useable roof coverings was limited. Shallow hips on the outside of the crescent would mean that the use of hip tiles would be unsightly and unreliable and on the inside of the crescent, open bedded valleys would be inconsistent with the overall design.

Norfolk based roofing contractors; Aspect Roofing chose our Dry Fix Valley Trough for low profile tiles for both the hip and valley detail due to their close-cut appearance on this new build project and the fact that they cut fixing time by up to 50%. Paul Elliston, General Manager at Aspect commented, “The proposition was for the product to be aesthetically pleasing and practical. Hambleside Danelaw’s Dry Fix Valley Troughs fulfil both of these elements at the same time as being easy to install and they provide good cover.”

The developer was extremely happy with the principle and the countless advantages that go alongside using this leading Dry Fix brand.

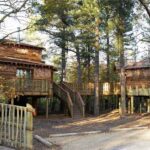

The ‘new for 2012’ two-storey Treehouses at the Centre Parcs Holiday Villages have been fitted with Hambleside Danelaw’s Dry Fix mortarless GRP Valley Troughs, meaning that Hambleside’s roofing products have yet again been specified for another project of a top quality brand.

The ‘new for 2012’ two-storey Treehouses at the Centre Parcs Holiday Villages have been fitted with Hambleside Danelaw’s Dry Fix mortarless GRP Valley Troughs, meaning that Hambleside’s roofing products have yet again been specified for another project of a top quality brand.

Other prestigious buildings with Hambleside products installed are the McLaren F1 headquarters, the British Museum, London Zoo’s Gorilla Kingdom, Durlston Castle at a World Heritage Site, and Marks and Spencer’s largest distribution centre.

Roofed using cedar wood shingles, not a common choice of roof covering in the UK, the Treehouses at Sherwood Forest and Longleat Forest are designed for families or friends who want the ‘ultimate’ Centre Parcs experience with views of the forest. The luxury features include a games den and infrared physiotherm room.

Blue Lines Roofing Ltd with 25 years of specialist project experience chose Hambleside Danelaw’s Dry Fix mortarless GRP Valley Troughs in conjunction with Centre Parcs technical services because they complemented the Treehouses’ design and décor perfectly. John Boucher, managing director at Blue Lines, said: “We have been using Hambleside Danelaw’s products for 25 years. With their GRP valley troughs, you are getting good quality at a reasonable price.”

Hambleside Danelaw’s Dry Fix mortarless GRP Valley Trough creates a neat close-cut appearance on new build and refurbishment projects. It is ideal for complex jobs. Available in standard lead grey colour, the unique product cuts fixing time by up to 50%.

GRP valley troughs provide the following advantages over lead products

- up to half the cost of traditional lead installation

- semi-skilled fitting procedure

- pre-formed profiles are light in weight and easy to handle

- 30 year guarantee

- BBA approved

- does not streak or stain slates or tiles

- can be safely used with other products to recycle rainwater

- no value to the thief

- avoids health issues relating to the incorrect handling of lead

Hambleside Danelaw is the UK market leader for GRP flashing products, which includes the Dry Fix (mortarless) brand and Stormforce 225 mortar fix GRP flashings for roof and abutment wall applications. Other products include GRP Dry Verges, Dry Soakers, Dry Fix Bonding Gutters and RollOut Ridge and Hip Systems. Full technical support is provided. Production methods used within the UK manufacturing processes meet the criteria of the Carbon Trust for energy efficiency.

A high quality roofing solutions company has chosen Hambleside Danelaw’s Dry Fix mortarless GRP Valley Trough for a complicated roof on a Buckinghamshire care home. Malone Roofing went for the sustainable and quality solution offered by the British roofing products manufacturer when working in partnership with Castleoak on Lent Rise House, a new 60-bed care home in Burnham that forms part of Buckinghamshire County Council’s major Project Care reprovisioning programme.

A high quality roofing solutions company has chosen Hambleside Danelaw’s Dry Fix mortarless GRP Valley Trough for a complicated roof on a Buckinghamshire care home. Malone Roofing went for the sustainable and quality solution offered by the British roofing products manufacturer when working in partnership with Castleoak on Lent Rise House, a new 60-bed care home in Burnham that forms part of Buckinghamshire County Council’s major Project Care reprovisioning programme.

Alan Stagg, contract manager at Malone Roofing, said:

“The new care home has a complicated roof by industry standards so we needed roofing and ventilation products that were ideal for a complex job. We have used Hambleside Danelaw’s Dry Fix valley troughs before and the GRP material is the best for this type of work, especially as it offers a high performance and mortarless solution.”

Hambleside Danelaw’s Dry Fix mortarless GRP Valley Trough creates close-cut appearance on new build and refurbishment. Available in standard lead grey colour, the unique product cuts fixing time by up to 50%

GRP valley troughs provide the following advantages over lead products

- up to half the cost of traditional lead installation

- semi-skilled fitting procedure

- pre-formed profiles are light in weight and easy to handle

- 30 year guarantee

- BBA approved, complies with NFRC technical Bulletin 28

- does not streak or stain slates or tiles

- can be safely used with other products to recycle rainwater

- no value to the thief

Hambleside Danelaw is the UK market leader for GRP flashing products, which includes the Dry Fix (mortarless) brand and Stormforce 225 mortar fix GRP flashings for roof and wall applications. Other products include GRP Dry Verges, Dry Soakers, Dry Fix Bonding Gutters and RollOut Ridge and Hip Systems. Full technical support is provided. Production methods used within the UK manufacturing processes meet the criteria of the Carbon Trust for energy efficiency.

Cheddington Airfield played an important role in World War 2, as home of RAF operational training units. 70 years later, the estate is currently undergoing a re-generation scheme to modernise. Old and damaged Nissan Huts have been replaced with new steel fabricated industrial units to hold various new clubs and businesses and a new café has been constructed to service the business community.

The new build café is a single story brick building with a Double Roman tile roof. Hambleside Danelaw’s Dry Fix Valley Troughs for high profile tiles, HDL DVT/1, have been selected by Roof Craft from roofing merchant Advance Roofing, and now feature on the roof valley intersections. Roofcraft are experienced roofing contractors. They have been trading for over 25 years and have handled many jobs for local authorities in the Buckinghamshire area. Peter Thomson, Roof Craft, explained that he selected Hambleside Danelaw’s Dry Fix Valley Trough due to the obvious advantages of a mortarless option, plus the benefits of an installation process which is easy and straightforward and gives a neat, close cut finish.

JR Roofing installed Hambleside Danelaw HD TV15 series flush fitting tile vents across 150 roofs as part of a Community Energy Saving Programme, refurbishing Glasgow Housing Association building stock.

The tile vents were selected as a more cost effective option against competitor vents because of their unique increased airflow specification. At 15,000mm2 airflow, Danelaw’s tile vents can be installed at 1.5m spacings, whereas competitor vents with 10,000mm2 airflow would need to be spaced just 1m apart. Therefore on a project of this size, time and cost savings can be made whilst giving a high quality flush fitting finish.

JR Group have been committed to installing Hambleside Danelaw’s vents on refurbishment projects for this reason since discovering them 4 years ago. Whenever properties are being insulated to improve their energy rating, it is important to ensure adequate ventilation is also installed to avoid condensation.

The large farmhouse at Stone Shells Farm, Somerset, has recently been restored and as part of the project, some of Hambleside Danelaw’s products were selected for their high quality finish: Individual Dry Soaker for plain tiles (HD PCS), Conti-Soaker continuous dry soaker for tiled roofs (HDL CST) and Damp Proof Course (HDL DPC).

The large farmhouse at Stone Shells Farm, Somerset, has recently been restored and as part of the project, some of Hambleside Danelaw’s products were selected for their high quality finish: Individual Dry Soaker for plain tiles (HD PCS), Conti-Soaker continuous dry soaker for tiled roofs (HDL CST) and Damp Proof Course (HDL DPC).

The builder, Mike Dunlop, saw our GRP products on display at Bradfords Builders Merchants and decided to use them rather than lead because he was concerned about the recent rise in lead thefts. The ease with which these products can be installed also appealed because of the cost and time savings.

Bradfords Builders Merchants is an established merchant with multiple branches in the South West. Hambleside Danelaw GRP flashings and roof, cavity and underfloor ventilation products are available from merchants nationwide.

Dryseal Flat Roofing

Dryseal Approved Contractor, Michael Wheeler at RCC Roofing completed this recent project at the St. Moritz Hotel in Wadebridge, Cornwall.

RCC Roofing were contacted to install a new roof for a villa at St Moritz. Michael stated: “The builder constructed an additional roof on the top floor, which we slated vertically using high-quality Spanish slates. We also applied a Dryseal flat roof to the dormer rooftop.”

As part of the project, RCC Roofing replaced the existing Velux windows with new and installed Cambrian slates—consistent with those used across most villas at St Moritz—on the remaining slate roof areas. This was a particularly challenging project due to the strict time frame, as the villa needed to be ready for holiday lets. All works were carried out under a temporary roof, ensuring efficiency and protection from the elements. RCC Roofing successfully completed the roof meeting the builder’s requirements and deadline.

Dryseal Manager Andy Fell said “As ever, Mike’s team delivered the highest standards of work in the minimum available time, always with the client’s best interests at heart. The neatness of the finished work speaks for itself.”

This new-build house is situated in the quiet village of Boothby Graffoe, Lincolnshire. The work shown in these photos was completed April 2023 by C & C Fibreglass of Lincoln, and covers approximately 150m² over five separate areas, finished with a modular ‘cassette’ sedum green roof.

The team from C&C Fibreglass trained in September 2022 and this was their first Dryseal project which they started immediately after becoming approved.

Director Phil Chapman said “The team found the Dryseal system straightforward to install and easy to achieve a good finish with”.

After carrying out an inspection on site, Dryseal Manager Andy Fell said “It was a pleasure to see work which had been completed to such a high standard and proving a credit to Phil’s team. We were delighted to issue the 20-year Dryseal ‘Leak-free’ Guarantee”.

This stylish bespoke house was designed and built to high standards in 2018, the aim being to achieve very demanding aesthetics. Set in spacious grounds which emphasise the good looks of the house, Phil Boardman of P Q Fibreglassing Ltd commented “The demanding standards of construction and the need to integrate our roof waterproofing with other trades posed quite a few challenges for my team”.

Over a 6-month phased construction period, the Dryseal team had to ensure a complete seal to hidden areas inside chimneys, forming complicated detailing around the architectural rooflights and dressing the multiple decorative ‘rib’ trims whilst ensuring that the demanding weather didn’t defeat their progress. Phil admitted “The job nearly beat us at times, but we worked as a team to produce a really good, finished product that I am delighted to re-visit after 5 years has elapsed”.

The 5-year inspection interval which is recommended as part of the 20-year leak-free Dryseal guarantee has revealed no major problems and confirms that the system is performing to expected standards with minimal future maintenance requirements.

Dryseal Manager Andy Fell said “It is satisfying to inspect a job that I first saw during the installation 5 years go performing exactly as designed. The quality of finish achieved by P Q Fibreglassing is commendable.”

Extension with Green Roof

Long established Dryseal Approved Contractor Martin Shaw of Martin Shaw Roofing was approached by ARC Design Projects Ltd and asked to install waterproofing with a green roof on this large single storey extension of a Cheshire property.

He proposed the use of Dryseal due to its proven track record, ‘zero-falls’ BBA approval and ideal suitability for green roof installations.

After training as a Dryseal Approved Installer in 2013, Martin has completed many Dryseal roofs in the last decade, and has a great working relationship with the whole Dryseal team.

This project called for the roof covering to be installed in 3 phases to allow for follow-on trades. The first phase called for the installation, fixing and lamination of the Dryseal pre-cured GRP sheet and other components, the second phase being the top coat finish.

The third phase saw the installation of a green roof cassette system from Sedum Supply.

To complete the roof perimeter detailing, a bespoke aluminium coping was installed, giving this sleek looking project a crisp finish.

Handed over in February 2023, complete with the Dryseal 20-year leak-free guarantee, this prestige project emphasises the importance of a supplying a first class material and installing it with first class attention to detail.

The Quays at Burton Waters, Lincoln is situated within 15 minutes of Lincoln city centre and blends a unique mix of distinctive, high specification homes with a variety of commercial properties.

This award-winning development is set amid beautiful Lincolnshire countryside, next to the Fossdyke Navigation Canal, and is just two miles by water from the centre of the historic City of Lincoln.

Dutch-inspired architecture featuring balconies and terraces offers stunning views across the busy marina. Many of the New-England style homes situated around the waterside development have waterfront gardens with private jetties and balconies, often available as holiday lets.

A variety of quayside businesses ranging from an architectural practice to restaurants, a coffee

shop and high-end bars means that the area is very busy, with most moorings fully occupied.

Completed in 2013, all commercial properties have large expanses of patio and balcony areas finished using the unique Dryseal GRP membrane roofing system installed by long-established Hull roofing contractor L A Hall Ltd.

E G Swingler & Sons Ltd were set a challenge by Princethorpe College in 2020 to re-roof building 23, install new rooflights, upgrade the insulation and fit a new guaranteed Dryseal roof whilst keeping the building weather tight.

These photos which were taken in October 2021 after work had been successfully completed and snagged in accordance with AT Architects’ specification show the newly installed rooflights and fully finished Dryseal installation.

Dryseal Manager Andy Fell explained “The re-roofing work was diligently carried out during the summer recess in 2021 and as well as the upgraded insulation and rooflight work, involved a new exterior plywood roof deck. Work was completed to a very high standard by E G Swingler and now carries the 20 year ‘leak-free’ Dryseal Guarantee”.

The waterproofing of Chelsea Heights, Sheffield was started in 2020 by Mark Dickens of P D Contract Services, a long-standing Dryseal approved contractor. P D Contract Services are a multi-facetted widely experienced company supplying and fitting slating and tiling, wet lay GRP and zinc roofing as well as their system of choice in this instance, the Dryseal GRP Roofing system.

Mark chose the Dryseal system as he recognised the long-established market-tested product’s excellent performance combined with Agrément certification and the high manufacturing standards of ISO 9001, providing confidence to both the client and the architect.

Totalling around 1,800 m2 this project has been on-going since 2020 installed observing the high standards set by main contractor and developer PTA Developments Ltd. Incorporating exposed main roofs, balconies with a number of “green” roofs incorporating a significant insulation layer throughout. Overall roofing completion is anticipated in mid-2022.

Dryseal Manager Andy Fell said “We have really enjoyed working with Mark on this prestigious project as it has grown and developed over the months, concluding with an excellent high standard of finished work”.

An Unusual Building with a Wide Range of Uses

Artisan honey bees, bespoke sliding rooflights to allow roof level access, protected deck areas with planters; these are just some of the unusual features of this cooperative housing development in Sheffield.

Sheffield Architect Ted Tunnicliffe of Tatlow Stancer Architects decided to specify Dryseal yet again as the roof waterproofing on this town house development, having been happy with the system on several recent Sheffield projects including a large housing scheme and a health care clinic.

Andy Fell, Dryseal Manager for Hambleside Danelaw said “Having worked with Ted successfully on several projects since 2016, we were delighted to be able to help and have the opportunity to work on this specification. As you can see from the photographs, work has been completed to a high standard by Sheffield firm Cure Roofing who as ever completed their work with care.”

Get in touch with us via our contact page, or take a look at our approved contractors when planning to use Dryseal in your next project.

The Dryseal flat roofing system is suitable for a wide range of properties and is easy to maintain, offering your roof long-lasting protection from the elements. When installed by one of our approved contractors, Dryseal flat roofing system promises to be leak-free with an insurance backed warranty, meaning you can feel secure with the quality and product.

Dryseal has been installed on heritage buildings, as an approved lead replacement option under Secured by Design, as well as being perfect for residential and commercial properties with flat or low-pitched roofs. Made from GRP, this roofing system is BBA approved, and is ideal for complex detailing such as valleys, curved building edges, and dormer windows.

Before the roof was refurbished

At the end of its service life, you have the option to refurbish and apply a new topcoat, increasing the duration of the protection Dryseal offers. Customer Garth Jeffrey had his Dryseal roofing system installed two decades ago and decided it was well worth refurbishment.

In progress

He said: “My 20-year-old Dryseal roof had been fully watertight with no leaks and I was so satisfied that I decided to refurbish the roof to extend its life by another 20 years. Work to prepare the original covering and apply a new Dryseal top coat was completed in 2020 by MEH Builders & Joiners of Galashiels and I am very pleased with the results. The product is excellent, as was the service from MEH”.

Dryseal Manager Andy Fell added: “This is yet another great example of the Dryseal system successfully completing its first 20 year stint, with potential for another 20 years of extra time after a straightforward low cost top coat refurbishment. We are again delighted to be supplying added value and customer satisfaction whilst illustrating the sustainability of the Dryseal system”.

After project completion

Find an approved contractor for Dryseal Roofing System, or speak to a technical advisor today to learn how you can utilise Dryseal to protect your roof.

Conveniently located near Blackrock, Douglas and the city centre, these homes at Aylesbury are built to the highest specification and include a host of energy efficient features. Each house is beautifully finished to reflect this mature and fashionable part of Cork.

When a client buys a Centurion Home, the aim is for the house to be an investment for the future.

Eoin at Cork Fibreglass Ltd is pleased be working with Centurion Homes and is justifiably proud of the high standard of finished work that Dryseal helps him offer. Fitting Dryseal since 2013 Eoin has seen demand for specifications from architects and house builders grow.

Eoin said “Dryseal is proving ever more popular with specifiers and has become my flat roofing system of choice. Noel Barry and Ger Quinlan of Centurion Homes have expressed their delight with the Dryseal work I have completed for them at Aylesbury.”

Dryseal Manager Andy Fell said “Eoin has always been very keen to fit the Hambleside Danelaw Dryseal system and regularly exceeds the high standards of finish that we aim to achieve, as shown yet again on this prestigious development, where once again the quality shines through. Eoin’s work epitomises the high standards that we aspire to through the Dryseal brand.”

Dryseal continues to grow in popularity across Ireland.

For more information, please contact our team on: dryseal@hambleside-danelaw.co.uk

New House…

Dryseal is chosen again in preference to zinc.

This newly built project in Boyle Co Roscommon was originally intended to be finished with metal sheet but this was subsequently changed to Dryseal in 2018 after discussions with the architect.

The original design had been for a “standing seam” metal clad roof, but it was decided that the pitch was too low for a metal finish and with so many joints on such an exposed site it was deemed to be potentially prone to leaks, so the Dryseal GRP waterproofing membrane system was chosen.

Initially installer P Q Fibreglassing Ltd had decided to fit 18mm OSB3 on top of the 200mm insulation so they could then easily fix the standing “zinc” seams down. As this was potentially going to add a lot of cost, P Q Fibreglassing’s Phil Boardman said “We decided it was best to remove the OSB3 and then use Dryseal DP 40 stress plates with 240mm screws under all the simulated zinc seam upstands, choosing pop rivets to fix the zinc seams down to the flat sheet, hiding almost all of the fixing points and resulting in a neat, flat finish”.

Top—coated in a bespoke dark grey, the project was completed and handed over in 2019 to a very happy customer.

Neat work beats zinc!

Mihai Oprisan shows the way with first class construction and finish.

This beautifully finished residential extension was completed and handed over in July 2019 after a great deal of hard work and attention to detail.

Rather than opting for a traditional metal roof, Mihai chose to use the Dryseal system for cost and aesthetic reasons. As you can see from the high standard of finish on all elements of the extension and garage, Mihai is very uncompromising and strives to leave the best possible result for the client.

Technical Manager John Godley said, “In over twenty years of working with new Dryseal installations, I have rarely seen such high standards of work, which are a testament to Mihai’s attention to detail”.

The use of the Dryseal “rib” trim that you can see in these photographs involves careful attention to detail from the Dryseal installer but can lead to exceptional results as you see here, the added benefit being cost savings compared to a metal raised seam system.

Dryseal Manager Andy Fell is quoted “It is so heartening to see that pride in the job is still alive and kicking!”

Far from being a “pig sty”, this interesting bespoke self-build house belonging to Mark Elsigood at Church Stowe in Northamptonshire is due to be finished in late 2019. The building was named the “Pig Sty” to mark the location of the original building and was built by Mark himself with additional specialist sub-trades.

Mark chose to use Dryseal because of its strength, suitability for “green” roof waterproofing and for the renowned 20-year Agrément certified guarantee. The Dryseal was successfully installed by long-established family business E G Swingler Roofing who are also based in Northamptonshire.

Mark picked the Dryseal GRP roof membrane system having visited Stand 106 at the The National Self Build and Renovation Centre in Swindon, which is open every day attracting over 17,500 visitors per year to 250+ exhibits.

The National Self Build & Renovation Centre’s Managing Director, Harvey Fremlin, said: “As the UK’s only permanent self build visitor centre, our mission is to inspire, educate and offer impartial advice. We are delighted that Mark discovered the Dryseal system at the NSBRC. Andy and the team work hard to give our visitors great advice and service. The Pig Sty looks absolutely fantastic, and proves that self build allows people to create bespoke homes that suit their taste, budget and life-styles.”

You can see from the unusual design that the roof incorporates two balcony areas finished with stainless steel edge rails and tempered glass balustrades, providing both first-class visibility and safety, and allowing clear views of the nearby open countryside. The two balcony areas are planned to be finished with “sedum” mats to form a “green” roof.

Dryseal Manager Andy Fell said “We are pleased that Mark chose the Dryseal system to waterproof his new home and are very happy to have also supplied our 20-year “leak-free” Guarantee“.

After the project was complete, Mark said “Visiting the NSBRC allowed me to observe different products and their suitability for the self build project I was undertaking. Dryseal seemed to have all the characteristics that I needed in a flat roofing system. I am really pleased with the final results of the Dryseal system in waterproofing my dream home“.

Ceardean is a team of experienced architects, designers and specialist consultants based in Dublin 8. The practice aims to deliver aesthetically appealing buildings, working in strong collaboration with clients to achieve cost-effective and functional designs every time.

Such is the passion for energy-saving design within the Ceardean practice, that Chief Architect Derek Trenaman RIAI spent 5 years converting his 100 year old cottage in Sligo into a beautiful zero-energy dwelling

This pictured project in Crumlin, Dublin has almost doubled the usable space available, adding a contemporary flavour to what was a standard semi-detached dwelling. Using an innovative rainwater system that effectively hides the points where water discharges from roof level and using a beautiful larch exterior cladding to powerful effect, the crisp clean lines of the building make the corner of this Dublin street look really special.

Phil Boardman of PQ Fibreglassing Ltd said “Yet another high end Dryseal membrane roof completed with the all-important 20 year guarantee and insurance certificate marking over 6 years of continuously successful Ceardean Architect specified contracts.”

To download the pdf version, please click here.

Over the last 25 years, Dryseal has been used as an underfloor damp-proof membrane in a gymnasium, a liner for ponds and fountains, a damp-proof membrane in a lift shaft on a castle, and recently as a roof covering for a Container Home.

In early 2018, Phil Boardman of P Q Fibreglassing Ltd was asked to quote for the waterproofing of three sea containers which are now in use as storage units on the quay side at Dun Laoghaire Harbour, on the outskirts of Dublin.

The containers have a reinforced roof incorporating raised areas that act as structural ribs to give the steel roof rigidity and strength. Phil’s team levelled the roof surface using sheets of 25mm insulation board, leaving an even surface to work to. They then fixed the Dryseal system through into the steel roof, formed the laminate joints and finished with dark grey top coat.

A lightweight robust and flexible waterproofing membrane was called for and Dryseal was chosen for its superior properties.

Phil said “The priorities were to ensure that the system was securely fixed, completely waterproof and salt resistant. Dryseal fitted the bill all round”.

To download the pdf version, please click here.

Loud the Winds Howl, Loud the Waves Roar. The Roof Used to Leak, Now with Dryseal… No More!

In 2017, Steven Gillies of R S Gillies was approached to quote for re-roofing a 250 m² area of this historic hotel. Despite the rest of Scotland suffering from the Siberian weather and 300mm of snow, the warm Gulf Stream weather enabled Steven and his team to put aside their day-to-day boat building work and complete the re-roofing with the minimum of disruption in February 2018.

Steven said “We are really impressed with how easy the Dryseal system was to install and the high standard of finish we have been able to achieve. It’s great to know that we have helped preserve the fabric of this historic hotel”.

R S Gillies trained to install the Dryseal system back in 2013 , but have been so busy building boats at their yard in Kyleakin that this project represents their first good-sized roof since completing the course. Steven started his business over 20 years ago with initial support from the Prince’s Trust, Prince Charles’ charity to help young people thrive.

Mike Lemmon, Scotland Area Manager for Hambleside Danelaw said “A great finish to this project after a lot of hard work. We have enjoyed working with Steven and his team and look forward to the next job”.

During the summer of 2016, Dryseal Approved Contractor John Cossey of Ashford, Kent was approached by Vinci Facilities. Acting for Affinity Water, Vinci asked John to provide a waterproofing solution for the tired bitumen felt roof covering on this facility. The building which was built by the Folkestone Waterworks Company in 1932 was starting to show signs of ageing at roof level, and John decided that Dryseal was the obvious system to provide a long-term waterproof covering on this complex roof.

John Cossey said “Dryseal was ideally suited to extensive detailing to metre high parapets and sundry awkward interfaces. Work was completed successfully in January 2018, with a 20 year “leak free” guarantee”.

Another guaranteed success for Dryseal – Waterproofing the Waterworks!

This extension as part of a full house refurbishment on a property in Woodstock Road Oxford now benefits from a new Dryseal green roof.

Completed in June 2017, the Architect at the Client’s request specified this attractive and environmentally-friendly design. Dryseal, being the ideal waterproofing membrane for a green roof, was a natural choice, due its robust, aesthetic and non-pollutant properties. Bondright Roofing Services’ Erika Luckow said “We were contacted by Lee & Ross Architects in May 2016 following a CPD Seminar held by Hambleside Danelaw. We were told that they found Dryseal to be an attractive solution for their project in Oxford requiring a Green Roof system over the kitchen/family room on the extension. With the assistance of Andy Fell at Hambleside Danelaw, Dryseal was specified for the 37m² warm roof, finished with the ANS GrufeKit Green Roof sedum system and Scottish cobbles.” The installer Dawid Piasecki said; “The fitting was easy and was installed according to the manufacturer’s instructions; Dryseal is a really good system.”

The finishing touch?

The 20-year Dryseal insured water tightness guarantee.

Skerries (Irish: Na Sceirí, meaning “The Rocks”) is a seaside town in County Dublin, Ireland. The name comes from the Norse word skere which has descended into the Irish word na sceirí.

A lovely seaside resort with “picture postcard” characteristics, Skerries is very popular with visitors from Dublin for a weekend break or family summer holiday, with kite-surfing and water sports being high on visitors’ lists along with the high quality local seafood restaurants. The housing development at Ballygossan Park is proving very popular and is filling rapidly; almost as soon as each property is completed, the sale goes through!

There are 2,500 m2 of Dryseal roofs completed up to date on this site. Most of the new house types have a flat roof, varying in size from 10 m2 dormers to 90 m2 of main house roof. The dormers are fitted with decorative trims to imitate zinc on the cheeks and faces, with the top coat being specially blended to suit the architect’s choice of colour.

We are told that the first phase of development is for 102 houses with plans for a railway station, shops, and a school in the pipeline. The development is at the half-way stage, with construction by Noonan Construction continuing apace.

Dryseal Approved Contractor P Q Fibreglassing Ltd have been instrumental in introducing Dryseal to the Client and Architect and have completed all roofs to a very high standard.

The first installation was completed in 2016 to waterproof the Hub, including the Main Entrance and Circulation Area.

Construction is due for completion by O&D Construction Ltd during September 2017.

The Architect for this phase was again Plan A. Glenthorne High School is one of several school projects where Plan A have preferred Dryseal over other roofing membranes.

Plan A’s Architect Director Paul Ginever said “The school were very keen to invest in a product which would serve them for a long period of time rather than opting for a short-term cost saving option, and it was a decision that we were very happy to support. We have specified Dryseal on a number of public and private projects with confidence that it would contribute to the long-term robustness of the building fabric. We are very happy with the

finish and quality of installation”.

Dryseal Manager Andy Fell said “McGrath Roofing’s work enhances the qualities of Dryseal as a warm roof covering, as well as emphasising the versatility of the system when used for vertical work and detailing such as coping ecapsulation. We are delighted with the standard of installation and finished work”.

Bondright were keen to use the Dryseal system and Ressance proved to be receptive to the idea, as they had had a number of problems on projects where they had previously used pvc ‘single ply’ waterproofing.

Dryseal Manager Andy Fell said “A meeting with Nick Turner, Ressance Director of Design and David Creek, Project Manager proved to be successful in promoting the resilience of Dryseal along with the many industry accreditations which the system carries. The insured 20 year Guarantee also played a strong part in the presentation”.

Work commenced on the roofing installation on October 2015, with a high specification 0.13 W/m2 K U value being achieved using 150mm insulation over the existing woodwool decked structure. Despite some testing weather in October and November, Bondright rapidly achieved water tightness on both blocks totalling over 900 m2, and handover in early 2016.

Merchants Court is a short walk to a number of convenience stores, food outlets and Victoria Park, within walking distance of the town centre and transport hubs and just 600 metres from the Kennet and Avon Canal. Further details of the stylish development can be viewed on Ressance Website.

With everyone happy to have achieved a positive outcome on this prestigious project, we keenly look forward to working with Ressance again in the future.

Hull City Council, Trowbridge Housing, Bellway Homes, Trent & Dove Housing, Magenta Living…. and many more. These customers have one thing in common with Newark & Sherwood Homes whose properties use Dryseal on a range of flat roofs, bay tops and new build sheltered accommodation.

January 2016 saw a meeting with Newark & Sherwood Homes which resulted in Dryseal being specified for their re-roofing programme on flat roofs in the Edwinstowe, Boughton and Wellow areas of Nottinghamshire.

Work started in June 2016, with around 50 nr upgraded warm roofs now complete – well on the way to the anticipated 200 units which the contract should generate. Hambleside Danelaw have been working closely with contractors Malden Roofing and Cure Roofing, both of Sheffield, who have been working in tandem to provide a first class guaranteed result.

Dryseal Manager Andy Fell said “Dryseal is ideal for these types of roof – able to withstand some fairly heavy treatment whilst looking good and being easy to maintain. Housing Associations who are under pressure to cut costs after the 2015 Maximum Fair Rent rule changes continue to appreciate the long term ‘whole life’ cost benefits of the Dryseal flat roofing system. The peace of mind of our 20 year insured guarantee is the icing on the cake for the client. The system is only as good as the installer and these finished roofs by Malden and Cure Roofing are of a very high standard.”

St Mary’ s is the Grade 2* Listed Parish Church of Willesden where there has been worship since the year 938 and most of the present church dates back to the middle ages.It is home to the ancient Shrine of Our Lady of Willesden, and to the Holy Water of Willesden which flows underneath the church and is freely available.

s is the Grade 2* Listed Parish Church of Willesden where there has been worship since the year 938 and most of the present church dates back to the middle ages.It is home to the ancient Shrine of Our Lady of Willesden, and to the Holy Water of Willesden which flows underneath the church and is freely available.

McGrath Roofing Ltd re-lined two large valley gutters with Dryseal after they were completely stripped of lead by thieves. Dryseal holds Secured By Design accreditation, making it a great option for heritage buildings in order to deter thieves. Read more on this here.

Dryseal Approved Contractor Croft Roofing have been supplying and fitting Dryseal since 1995. Owner Tim Croft was approached by his long-standing customer Andy Harm to recommend a solution to roofing problems at Otley Golf Club. Local builder and Club member Andy had been asked to assist Secretary Peter Clarke in solving water ingress problems on the 270 m2 flat section of the Club House roof.

After an early inspection carried out in conjunction with Hambleside Danelaw, Tim found that the existing EPDM membrane covered roof was in need of an upgrade due to low levels of insulation, water ingress and ponding problems. Ejot were asked to recommend an approved fixing and carry out ‘pull-out’ tests to ensure the security of the fixings.

As the roof covers the Entrance area, Lounge and Kitchen, Tim’s workforce had to be very careful in carrying out their work. This included adding insulation, improving drainage and installing the Dryseal system whilst causing the minimum of disruption to the running of the 700 member Club. They also encapsulated the front parapet wall and replaced the original aluminium capping using joint-free Dryseal sealed copings, to minimise the chances of future problems.

“Croft Roofing have been very good and have been completely professional. The work proceeded as quoted and agreed, on time, within budget with excellent results” – Peter Clarke – Club Secretary

The original rounded river ballast finish was put aside during re-roofing work and then replaced on a new fleece layer to the main flat area, to minimise the chances of any of the original standing water being visible. In the event, the drainage measures taken by Tim’s employees resulted in a 90% reduction in the original ponding problem – a great result.

A final inspection for Guarantee was completed in July 2015, followed by completion and handover to another satisfied customer.

Dryseal was the material of choice for the green roof waterproofing on a recently constructed ‘Passive’ House in Easter Housebyres, Melrose, Scotland. The term ‘Passive’ house (Passivhaus in German) refers to a rigorous, voluntary standard for energy efficiency in buildings, reducing their ecological footprint. It results in an ultra low-energy building that requires little input for space heating or cooling.

Malcolm Horsburgh of MEH Builders and Joiners chose robust and lightweight Dryseal to line the green roof on 130m2 of the main roof and 56m2 of the lower area and balcony. GRP was specified by the architect for the roof membrane and approved contractors MEH felt Dryseal was the obvious choice.

The Dryseal system is ideal for green roofs as it eradicates the need for a root barrier. The superior roofing material is also safe with potable water, as there is no contamination from the surface that might interfere with growth of the vegetation. Dryseal has other environmental advantages; it has the lowest embodied carbon of all its competitors (for more information, please contact us).

Malcolm from MEH said: “By using Dryseal as opposed to other GRP ‘wet lay’ products we were able to leave out the additional layer of plywood required for wet lay systems and increase the thickness of insulation by 20mm. More to the point, we also saved the client money!”

Building the Melrose ‘Passive’ House began in January 2014, with the project due to be finished in January 2015. The site is on a slope, making the build tricky at times, but the Dryseal went on smoothly, taking four contractors only 6 days to install. Owner Patricia Touw said Malcolm and his team paid “great attention to detail”.

The Dryseal system carries a 20-year leak free guarantee with an insurance warranty; a perfect choice for your roof.

The work started in September; approved Dryseal contractor Hamish Graham worked on the project with his team at G C F Joiners. The contractors installed 40m2 of Dryseal on three dormers; the work was executed with precision and only took two days. G.C.F. Joiners and Contractors Ltd commented,

“G.C.F. Joiners and Contractors Ltd are honoured to be chosen for such a prestigious project and look forward to carrying out future works”

Dryseal is used on many heritage projects due to its excellent durability. As those who install Dryseal have to be approved contractors, the work carried out is always first class. Dryseal emulates the classic lead look as it can be finished using decorative roll trims to imitate a heritage installation.

The Castle is located on the West Coast of Scotland, in Lochaber. The striking Mingary Castle, which is set in a classic Highland landscape, was used as a stronghold protecting the north end of the Sound of Mull, and the more southern islands of Tiree, Coll and Eigg. The Gaelic architecture remains as imposing now as it did back in medieval times.

The Castle’s restoration is due to the owner, Donald Houston, setting up Mingary Castle Preservation & Restoration Trust. A huge amount of work is going into the restoration of the heritage building, with local craftsmanship leading the effort. To read more about the project visit www.mingarycastletrust.co.uk/mingarycastletrust/.

Hambleside Danelaw is pleased to be involved in the work, and Dryseal is the ideal component for the future of the castle. For further details on Dryseal or how to become an approved Dryseal contractor, please call 01327 701900 or email dryseal@hambleside-danelaw.co.uk.

Dryseal system budget prices were incorporated into an extensive improvements programme and work began in 2013 after the usual rigorous tender process. Dryseal Approved Contractor Avonside Commercial & Industrial Roofing (Midlands) started work on the Sports Hall, introducing additional insulation whilst fitting the Dryseal RibTec membrane over the existing coverings, after suitable preparation. The re-roof was carried out in tandem with Whitesales who were engaged to install the new triple glazed rooflight units. Work was successfully completed after six weeks in late 2013, with the newly watertight Sports Hall quickly attracting positive comments due to the improved insulation level and brighter interior.

The main lower level Gymnasium and Dance Studio roofs totalling over 1,000 m2 were re-roofed over a busy 8 week period between March and May 2014. Once the chippings had been removed, the existing waterproofing was again able to be retained as a vapour check layer, adding 50mm of Celotex TD 4000 polyisocyanurate insulation board in the Dryseal over-roof. Various items of redundant plant and equipment were also removed from the roof at the same time as re-roofing. The whole operation was able to be carried out whilst the building was in daily use and was completed without disruption to the Centre, thus ensuring important uninterrupted income.

Another successful Dryseal roof refurbishment completed on time and within budget, prompted Dryseal Manager Andy Fell to say “This effective and efficient re-roof illustrates the major benefits of the Dryseal component based GRP roofing system when used in a refurbishment scheme. Speed, cleanliness, improved insulation and lack of disruption all contributed to the high level of satisfaction expressed by the Management of the Leisure Centre.

The highly regarded St Joseph’s Surgery and Diagnostic Centre in Sligo, Ireland was urgently in need of a new roof covering over the main hospital building. After several months of discussion, the hospital chose to use the Dryseal component based GRP roofing system supplied by Approved Installer PQ Fibreglassing to complete the re-waterproofing and insulation upgrade works. The 750 m2 area comprised six roofs covered with failing rock asphalt on the original concrete substrate.

The Hospital was closed on a Thursday in April 2014 to allow the car park to be used for a crane to load out all delivered materials to roof level, to ensure that roof level production would be maximised. PQ Fibreglassing’s dedicated team of seven then worked over six long weekends, whilst the hospital was closed, to ensure that the day-to-day function of the building would not be compromised.

One of the main aims of the project, in addition to the replacement waterproofing system, was to reduce the hospital’s considerable heating costs. This was achieved by introducing two layers of 50mm Kingspan TR26 insulation to form a ‘warm’ roof build up under the Dryseal membrane, using the original asphalt as a vapour check layer. PQ Fibreglassing also renewed eight roof lights with new high thermal efficiency triple glazed Velux units.

The addition of DukMat safety walkway matting and self-weighted perimeter safety handrail ensure that the newly installed Dryseal roof can be safely inspected and maintained to ensure its longevity. With a 20 year insured guarantee that can be extended in year 19 by refurbishment of the top-coat, the Agrément certified system can have its life extended almost indefinitely.

A 35% reduction in heating oil costs is an immediate positive outcome of the roof’s insulation upgrade. Having used the Dryseal Flat Sheet membrane system finished in dark grey to eliminate all roof leaks, the hospital’s Premises Manager referred to this as a “perfect” result.

After installing a temporary waterproofing structure, the church took action by ringing Hambleside Danelaw about the Dryseal system. They had found out about the extensive Dryseal work done in Bromsgrove at the St John the Baptist church in 2012.

Dryseal Manager Andy Fell said “I was called by Brian Cooke from the church Fabric Committee. Brian was extremely annoyed about the theft, but fairly stoical about the fortunes of the church compared to other less fortunate ones. He expressed a keen interest in Dryseal and was sent some technical information along with photos of other church work. Within days, Approved Contractor Paul Lambert of Paul’s of Burbage had inspected the roof and quoted. The quotation was accepted in early 2014 and the Dryseal RibTec re-roofing work completed in April 2014”.

Sadly, the organ which was newly installed in June 2013, is situated in the South Aisle and stands directly below where the lead had been stolen from the roof. It was severely damaged as a result of the lead theft and had to be repaired at considerable expense to the church, as insurers would not provide adequate cover for the theft of metals from roofs. Now fully restored, the organ is being used once again. Church services and other activities can also now be held in the church this year without fear of further lead thefts and floods in the south aisle. This includes the series of annual classical concerts , now in its 43rd year which attracts widespread interest from the surrounding area. Details can be found at www.musicatleamingtonhastings.co.uk

Paul Lambert was extremely pleased with the finished roof “We installed the Dryseal system, complete with imitation rolls and roof void ventilation along the whole roof on both levels. The lead that was left behind by the thieves was sold to a scrap yard and paid directly back to the church. We are extremely happy about the job, the church were also very pleased with the finished roof and the time taken”.

Hambleside Danelaw are delighted to have been able to assist in preserving a part of English history with another memorable Dryseal project.

Hambleside Danelaw’s component based roofing system Dryseal has been selected for a complicated domestic roofing project on the edge of the popular Devon village of Stoke Canon.

The Round House is a remarkable four-bedroom house that was designed by architects Peter Blundell-Jones and Gillian Smith. Completed in 1976, it was originally built for the parents of Blundell-Jones as their retirement home and was his first project. Having never before been on the open market, the Round House has now been sold and is being completely renovated – including the replacement of the original felt roof covering with an insulated Dryseal system.

The new owners, Martin and Christine Cridford wanted a replacement roof that complimented the design of this interesting house. They considered the roof to be a main feature of the building and wanted it to have a good appearance from the garden. They originally looked at installing a new metal roof. This was going to be costly and many metal roofing contractors were unwilling to take on the job as it was too complex. Those who said they could do it wanted to strip the roof structure completely and cover the house with shrink-wrapped scaffolding to keep it dry while the works were carried out. This proposal did not fit in with the owners’ ideas and other options were explored.

In February 2013 Martin approached Dryseal Approved Contractors DA Somerwill about the Dryseal alternative. David Somerwill and Andy Fell, Dryseal Manager carried out a full roof survey and confirmed Dryseal as a sensible and cost effective solution. Hambleside Danelaw formulated the specification for the renewal of the roof covering including a 20 year insurance backed guarantee.

Dryseal can usually overlay existing roofing material so there was no need to need to strip the original roof covering in this instance. Laid over a 50mm insulation board to further enhance the U value of the existing wood wool slabbed structure, the Dryseal was fixed using SFS Intec TPR-L aluminium peel rivets and DP40 nylon stress plates. The appearance of a sheet metal roof was achieved by the use of carefully spaced decorative roll trims and dark grey polyester top coat.

Martin and Christine commented, “We are very pleased with the final appearance of the roof and the attention to detail by David Somerwill and his team. We know they are very proud of the completed roof. The Dryseal guarantee gives us peace of mind that we have a roof that will last into the future. With Dryseal the house has the roof it should have had when it was built.”

The Dryseal system is ideal for flat and low pitched roofing and is manufactured in the UK.

The roof had previously been renewed using an asphalt covering which had failed after only five years, causing water ingress to damage the original roof deck. LEP opted to install a scaffold and sheeting temporary roof over the whole building to protect the interior whilst the work was undertaken. Plywood and a vapour control layer were fitted to replace the damaged roof deck and the insulation was upgraded with a tapered PIR insulation system, finished with the Dryseal system. New rooflights from Coxdome were also incorporated into the project to enhance the quality of natural light into the interior of the cottage.

The works were carried out by Dryseal Approved Contractors Allied Roofing (NW) Ltd. When complete, the building was completely watertight and the occupants of the cottage have commented on how much warmer and brighter the inside of their home is now. Allied Roofing showed respect to the community with minimum disruption to the neighbours, who had been especially concerned about potential noise and upset during the works. Care also had to be taken not to interfere with the roof of the adjoining transformer building in view of the stringent conditions imposed by the local Utility Company.

Andrew Kepczyk, lead designer for LEP commented, “We needed something with guaranteed material and workmanship that would provide certainty for the charitable trust. The representatives involved from Hambleside Danelaw had a clear understanding of their material and our requirements. The support we received at design stage contributed greatly to the success of the completion of the work.”

Another successfully completed project benefitting from the Dryseal 20 year independent insurance backed guarantee and warranty.

Chosen for its robust nature, 20 year guarantee and ability to mimic the appearance of a lead sheet roof, Dryseal was installed at the National Trust’s request by Rowsell Roofing of Yeovil, an approved Dryseal contractor, in March 2013.

The refurbishment involved the removal of a dilapidated fibre cement sheet roof from the conservatory, the decayed decking and felt roof over the Utility area, with re-instatement using Dryseal fitted over plywood. The Dryseal was finished in dark grey with a UV protective top coat and completed with decorative roll trims to give a lead effect and lead-like appearance.

Dryseal Manager Andy Fell said “Nick and Nathan of Rowsell Roofing completed a first class job with exemplary attention to detail and a pride in their work that is a joy to see. The feedback from the client echoes this”.

Hambleside Danelaw is delighted to be a part of another National Trust project in Buckinghamshire. Marlow Place, a 17th century Georgian property is in need of new flat roof areas and guttering and it has been requested that Dryseal replace the lead sheeting due to its proven reputation as a sensible alternative to lead.

Stolen lead replaced with Dryseal

In June 2012, it was reported in the local press that Hythe Bowls Club, in Kent, had become yet another victim of the lead theft epidemic rife in England in recent years. Their clock tower roof had been stripped of lead by thieves and the timber structure left open to the elements. Hambleside Danelaw were alerted to the problem and our Dryseal Manager Andy Fell passed on the details to the local Approved Dryseal Contractor, John Williams & Co (Contracting) Ltd of Lympne, Kent.

It soon emerged that, not only were John Williams familiar with the Bowls Club, but they had also originally installed the clock tower structure and lead covering, when the pavilion had been built. John Williams quickly got in touch with the Bowls Club, paid a visit and surveyed the damage. They quoted to re-instate the roof covering with Dryseal and, within days, the Bowls Club clock tower roof was as good as new.

Being manufactured from GRP (Glass Reinforced Polyester), Dryseal has no scrap value and is therefore of no use to thieves. As you can see from the photograph, the new Dryseal covering looks in keeping and blends in well with the building, the original weather vane having been retained and secured over the new roof covering. Another satisfied customer!

Is this the ultimate test for a glass fibre roofing system?

Is this the ultimate test for a glass fibre roofing system?

One of our Dryseal Contractors Mike Williams of FuturA Roof Limited has recently completed the construction of a Bob Cat model jet aeroplane.

It is propelled by a Wren 44 gold turbine, but the interesting bit for us is that the wings have been joined to the fuselage by using the same laminating components that we use within our Dryseal fibreglass roofing system.

Not only that, but our new stress plate, code DP 40, has also been used within the construction. The model has successfully flown at speeds in excess of 200mph (330km/h) and has endured 5 g forces during sharp banking manoeuvres. The model plane has been photographed in flight by Alan Townsend and this photo shows clearly the wing section and the stress plates all in action!

Not only that, but our new stress plate, code DP 40, has also been used within the construction. The model has successfully flown at speeds in excess of 200mph (330km/h) and has endured 5 g forces during sharp banking manoeuvres. The model plane has been photographed in flight by Alan Townsend and this photo shows clearly the wing section and the stress plates all in action!

That’s very fast for a Dryseal flat roof which is usually stationary, although it has been used to provide the roof surface on a railway carriage – but that’s another story!

Dryseal used on a ‘barrel vault’ shaped roof

Dryseal has been installed on a Georgian period house in Vergemount, Dublin. The client, who happened to be a qualified Architect specified Dryseal and Approved Contractors, PQ Fibreglassing based in County Longford, Ireland, were appointed to complete the works. The building is overlooked therefore the architect stressed the importance of a high quality, neat and flat finish. When comparing alternative roofing options, Dryseal was the best product for the job.

One of the roofs was a traditional ‘barrel vault’ which required specialist skill to achieve the impressive results, cleverly using roll details and other Dryseal trims, making the end product look like a clean lead finish. The client is thrilled with the results and will be specifying Dryseal in future projects now that its versatility has been proven.

In Woodlesford, West Yorkshire, the former church of All Saints has been converted into residential accommodation. As part of the conversion, the old spire was removed and the roof space capped in keeping with the building style. Dryseal was chosen to fit the budget whilst having a lead-like appearance, especially with added lead roll detailing.

9 years on, our Technical Manager John Godley was passing the building and had the opportunity to take a photograph, demonstrating how effective Dryseal has proven in this lead replacement installation.

Covered with a variety of materials, the 3 main roofs spread out over 1800 square metres comprising Technology, Sports and Teaching blocks. Hambleside Danelaw’s Dryseal roofing system offered an instant practical lightweight solution with a high quality finish.

As Dryseal is a component based mechanically fixed system, it allowed an additional 60mm of rigid insulation board to be overlaid directly onto the existing roof providing cost effective and instant waterproof protection. Due to the unique nature of Dryseal any moisture left in the old roof would be dissipated through roof edge ventilation possible by not sealing the edges. The roof was finished in a bespoke pale blue (RAL 5024) top coat to match one of the colours of the school crest. The top coat, which provides protection from UV degradation, is usually supplied in light and dark grey as standard but can be customised to match a range of colour finishes.

Hambleside Danelaw believe that a major precedent has been set for churches and other historic buildings by the first ever installation of a modern glass reinforced polyester (GRP) roofing system on a Grade I listed English church.